AMIS - The Process and The Journey

A short video highlighting our Amis process and the journey

From Chaos to Control with AMIS - The Process and The Journey

MCP’s Asset Maintenance Improvement System (AMIS) isn’t just another box-ticking exercise.

It’s a journey…

There's an unspoken truth: staying reactive with your maintenance means you’re always one step behind.

This means that, to make long-lasting change, new structures, processes, practices, and procedures have to be developed, deployed, and then ‘embedded’ into the business. The AMIS journey helps organisations shift from a culture of constant firefighting to one where maintenance supports, and even drives the overall business performance. Here’s a closer look at insights, tools, and strategies to help maintenance teams like yours see a clearer path forward.

STEP 1

Breaking free of The Vicious Cycle of Reactive Maintenance

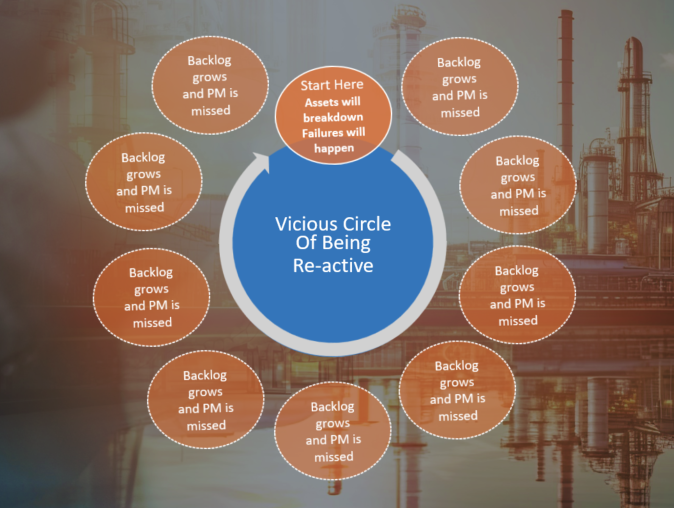

The Vicious Circle Of Being Re-active

Maintenance departments can often feel like they’re fighting a losing battle. Understaffed, overworked, and tasked with simply "keeping things going," they are constantly stretched. This cycle - what we refer to as "The Vicious Circle of Being Reactive" starts with missed preventive maintenance, moves to quick fixes, and ultimately leads to a mounting backlog of breakdowns. And so the cycle continues.

Our AMIS system, developed over 30 years ago, serves as a key tool to assess maintenance performance and identify areas for enhancement, therefore, offers a way to disrupt this. By focusing on long-term change rather than short-term fixes, it guides teams in establishing control, order, and ultimately, excellence in maintenance.

STEP 2

Building a Comprehensive Baseline for Maintenance Excellence with the AMIS Assessment

Every AMIS journey begins with a thorough assessment of your current maintenance operations. This isn’t a "tick-box" task; it’s a focused, on average three-day process aimed at capturing both immediate challenges and underlying improvement opportunities.

The assessment starts with a pre-visit questionnaire to gather crucial background information on maintenance practices, costs, and performance. Using this, the AMIS team prepares a bespoke agenda for their on-site visit, where they’ll work closely with your key personnel through in-depth observations, interviews, and data collection. Key areas of focus include:

Labour vs. Material Costs: Analysing the balance between manpower and material expenses.

Stock Turnover: Reviewing inventory practices to meet maintenance needs efficiently.

Resource Allocation: Assessing how resources are split between production and maintenance to support long-term asset reliability.

Contractor vs. In-House Maintenance: Evaluating cost-effectiveness and the role of outsourced work.

Productivity Ratios: Measuring hands-on maintenance work versus support functions to identify potential productivity gains.

An example of an AMIS Output Assessment

Each of these metrics is benchmarked against industry standards, offering sector-specific insights that highlight strengths and areas for improvement. The outcome? A tailored report packed with actionable recommendations, designed to set your team up for lasting success with clear priorities and realistic goals.

STEP 3

Beginning The AMIS Journey with a Guide for Setting Standards and Measuring Progress

Benchmarking is a cornerstone of the AMIS journey. By tracking and scoring performance in key maintenance areas, the AMIS tool allows organisations to see exactly how they measure up against sector-specific standards. More importantly, it helps build a sense of achievement by showing progress over time.

The Amis Assessment key findings:

Opportunities for Improvements

Implementation Requirements

Strategy and Plan

Communication and Culture Change

Implementation Route Map

Governance and Support Required

For example, as teams implement recommendations from the initial assessment, the benchmarking tool provides tangible evidence of improvement like reductions in unplanned work, better stock management and improved productivity metrics. These insights don’t just show what’s working; they help teams celebrate the wins and build momentum.

STEP 4

Reaching The Best Practise Benchmark - The Road to Sustainable Excellence

The AMIS Pyramid

One of the most valuable lessons from the AMIS journey is that reaching maintenance excellence takes time, commitment, and structured guidance. It’s a marathon, not a sprint, and along the way, certain insights and workstreams are crucial to sustaining progress:

Engagement Across the Board: Effective maintenance transformation isn’t isolated to one department. Operations, quality control, and leadership must all be on board to bring about meaningful change, creating a united approach across functions.

Clear Communication at Every Step: Regular updates and transparent communication keep everyone engaged, aligned, and motivated, especially when challenges arise.

Prioritising Holistic Benefits: While financial gains are significant, equally important are the “soft” benefits, such as team morale, a proactive mindset, and enhanced collaboration, which support ongoing growth alongside measurable data.

An Example of AMIS Journey to Best Practice

The journey toward maintenance excellence typically spans three to five years, and AMIS helps clients navigate each stage with a structured route map. Visualised as a pyramid, this journey moves from a foundation of chaotic and reactive practices up to “World Class” or "Best Practice" levels of reliability and efficiency. Each layer of the pyramid represents a step in elevating maintenance operations from basic control to predictive, proactive excellence.

Through these workstreams and a phased approach, AMIS provides the necessary tools and insights to transform maintenance from a challenge into a strategic advantage - positioning your organisation at the forefront of best practices in asset management.

STEP 5

The Impact of Reassessment in Driving Continuous Improvement

A graph showing the overall AMIS Process

A crucial element of the AMIS journey is the reassessment phase, where progress is measured and strategies are adjusted to stay aligned with evolving goals. This periodic review allows teams to evaluate their achievements against the benchmarks set in the initial assessment, providing clear insights into what’s working and where further improvement is needed. Reassessments help maintain momentum, reinforce commitment to best practices, and adapt plans as the organisation grows. By revisiting and refining strategies, the reassessment process ensures that maintenance excellence isn’t just achieved but sustained over the long-term.

KEY LESSONS

The Payoff: Maintenance as a Driver, Not a Drain

It must be acknowledged that the journey to maintenance excellence will take years, not weeks or months

There is the need to plan the journey and regularly monitor progress

Some method of benchmarking assessment is required to support the journey – AMIS does this

Engagement with operations, quality and senior management is essential

from the outsetContinually communicate with the maintenance team and other stakeholders

Measure the financial and soft benefits throughout the journey

Organisations that follow the AMIS journey don’t just see fewer breakdowns or happier maintenance teams. They see maintenance transform from a cost centre into a value-adding asset. These organisations save on costs, minimise downtime, and maximise equipment reliability - freeing teams to focus on more strategic priorities.

Are You Ready?

If you’re ready to break free from the reactive cycle and start building a high-performing maintenance culture, AMIS can help guide the way.